Download the whitepaper to learn more about Peak Irradiance & Energy Density for your UV Curing Application

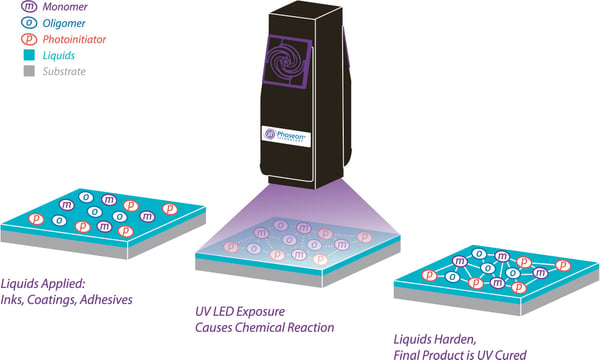

In the printing industry, professional have used an array of techniques, including forced air, infrared heat, election beam and UV light to dry inks, coatings and adhesives on everything from newspapers and magazines, to flexible and rigid packaging, labels and signage. In industrial applications, energy from conventional ultraviolet (UV) arc and microwave lamps is often used to cure adhesives, coatings, paints and varnishes.

Historically, these methods have worked with various degrees of success, albeit with excessive heat and limited control of the final product, often resulting in less-than-perfect results and excessive scrappage.

While many manufacturers continue to use a broad range of techniques for their curing applications, an increasing number are embracing UV LED due its numerous benefits, including the ability to generate high yields, reduced scrap, lower running and maintenance costs and precision control.

Download the white paper to understand the difference between irradiance and energy density, but why both matter to UV curing.